Permanent Magnet for DC Stepper Motors

| Price: | 0.1~12.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

SMT-0145

Production Capacity:

100000pcs/week

Delivery Date:

15 days

Composition:

Neodymium

Material:

Sintered NdFeB magnets

Coating:

Nickel, Zinc, Epoxy

Means of Transport:

Ocean,Land,Air

Packing:

Polybag, Cartons

Product Type:

Rare Earth Magnet

Brand Name:

Smart

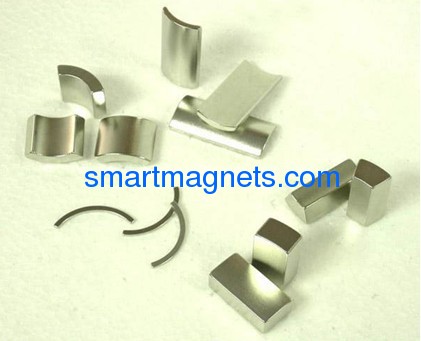

Shape:

Segment, Arc, Tile

Grade:

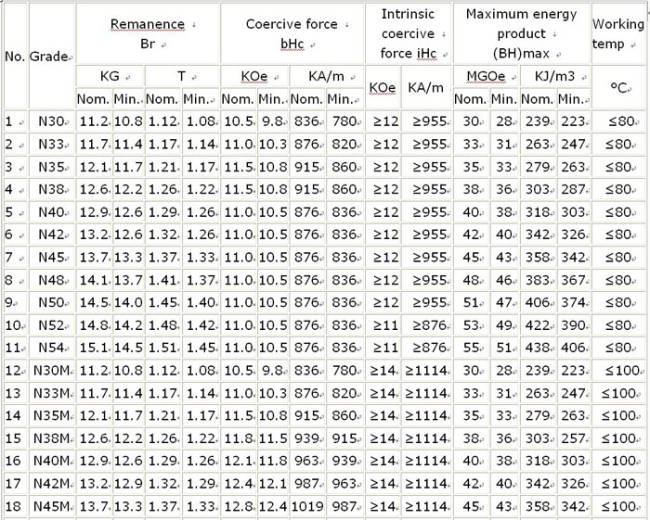

N30-N54, N30M-N52M, N30H-N5...

1.max continuous working temperature

2.Shape: Arc,segment

3.Plating: Ni,Zn,Epoxy,Telfon

4.stable performance

Neodymium magnet is the strongest magnet in the world till now that can lift up to 1000 times its own weight, it is mainly made of Neodymium, Iron and Boron. It is high remanence, high coercive force, high energy product and high performance/cost ratio. Neodymium magnet is anisotropic and only magnetized in one direction.

Feathers of Permanent Magnet DC Stepper Motors:

1. Materials: Neodymium-Iron-Boron;

2. Technology: Utilizes new Sintered NdFeB magnet techniques and equipment such as strip casting, HDDR technology;

3. Magnetic properties: High coercive force, the max operation temperature is up to 240°C or 464°F;

4. Grades of Permanent Magnet DC Stepper Motors: N30-N54, N30M-N52M, N30H-N50H, N30SH-N45SH, N28UH-N42UH, N26EH-N38EH, N28AH-N35AH;

5. Shapes: segment / tile / arc magnets,;

6. Sizes: OR x IR x H x Degree, Customized;

7. Tolerance: ±0.05mm, Customized;

6. Sizes: OR x IR x H x Degree, Customized;

7. Tolerance: ±0.05mm, Customized;

8. Coatings of Permanent Magnet DC Stepper Motors: Passivation, Nickel, Zinc, Tin, Aurum, Copper, Epoxy, Chemical, etc.

Surface | Coating | Thickness (Microns) | Color | Resistance |

Passivation | 1 | Silver grey | Temporary protection | |

Nickel | Ni+Ni | 10-20 | Silver bright | Excellent to humidity |

Ni+Cu+Ni | ||||

Zinc | Zn | 8-20 | Shining light blue | Good to salt spray |

Cu-Zn | Shining color | Excellent to salt spray | ||

Tin | Ni+Cu+Sn | 15-20 | Silver | Superior to humidity |

Aurum | Ni+Cu+Au | 10-20 | Shining gold | Superior to humidity |

Copper | Ni+Cu | 10-20 | Shining gold color | Temporary treatment |

Epoxy | Ni+Cu+Epoxy | 15-25 | Black, red, grey color | Excellent to climate humidity and salt spray |

Zn+Epoxy | ||||

Chemical | Ni | 10-20 | Silver grey | Excellent to humidity |

Despription of Permanent Magnet DC Stepper Motors: Permanent Magnet DC Stepper Motors, Arc neodymium motor magnet

1.Shape: Arc,Segment

2.High working Temp.

3.Grade:M,H,SH,UH,EH,AH

4.Appliaction of Permanent Magnet DC Stepper Motors:Motors, sensor, Sintered Neodymium Stepping Motor Permanent Magnet, Permanent Magnet DC Stepper Motor : is one of the high performance rare earth permanent magnets, which use neodymium (Nd), iron (Fe), and boron (B) as their main ingredients.

1. The NdFeB magnet has high remanence, high coercive force, high energy product and high ratio between performance value and product cost.

2. It can be easily formed into various sizes.

3. Smaller size and lighter weight in designing devices

4. Advantages:

a) High energy

b) Very high Hc and Hci output

c) More economical than SmCo

d) Wonderful performance at ambient temperature

5.High energy range from 30MGOe to 53MGOe with wonderful coercive force

6. For most applications, coating or plating is recommended.

7. Disadvantages:

a) Working temperature is below 220°C.

b) Prone to oxidation than other magnet alloys

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Dc Permanent Magnet

Permanent Magnet Dc Motor

DC Motors

Hybrid Stepper Motors

Magnet Motors

Permanent Magnet

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

SMART YEAH LIMITED [China (Mainland)]

Business Type:Manufacturer, Trading Company, Distributor/Wholesaler

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)

You May Like:

Product (645)

- NdFeB magnet (299)

- Flexible magnet (40)

- Fridge magnet (27)

- Magnetic Jewelry (241)

- Magnetic assembly (38)